As I explained in my last post, this year I have been growing japanese indigo from some seeds I got with some pretty cards. I tried the ice extraction first as it seemed simpler, and after having such good results with that I decided to stop feeling daunted and give a proper vat a go. There are many recipes online for indigo vats, mostly from dried indigo, and I started to get a little overwhelmed with all the options. It didn’t help that almost all the instructions were along the lines of ‘for X indigo powder you need Y this and Z this’, and not having indigo powder, that wasn’t helpful. So I decided to think about what actually is going on, and how I can achieve that.

The first step is extracting the indigo from the leaves. I didn’t need a flocculating agent, which is what makes the particles clump together and fall out of suspension, as I was planning to use the vat straight away, so all I needed to do was get the pigment out of the leaves and into the water. I decided the easiest way was to fill my dyepot with hot tap water (at 50C) and chuck the leaves I had into it.

After 24 hours the pigment should be out of the leaves, then I’d need to get rid of the plant matter and raise the pH of the vat. I have washing soda and caustic soda here, and decided to go with the latter, as the former is a rather weak alkali. I was unsure how much to use, then found this chart. I calculated how much water was in my vat (around 8.5l) and knew I’d need in the region of 10g to get the pH where I wanted it, which is around 10-11.5 for cotton (8.5-9.5 for protein fibres). It was at this point I realised that all the info I’d found about how much alkali and reducing agent per X of indigo, well, it actually didnt matter how much indigo was there, the important thing was how much water there is, as that is what affects the pH and contains all the naughty oxygen we want to get rid of (futurevampy says this isn’t quite accurate, but never mind!). So, again following the chart linked above, I decided I’d need around 30g of hydros (Sodium Hydrosulphite/Sodium Dithionite) which I’d picked up from Willo Fibres at FibreEast.

Okay, the plan was formed, I understood in general terms the chemistry of what was happening, now all I had to do was get on with it.

I picked all my remaining indigo, which wasn’t as much as I’d have liked; 970g total, around 350 of which was stems. Next year I will grow far more!

I pulled all the leaves off and put them into the pan and covered them with hot tap water at 50C. The pan was placed in a plastic bucket surrounded with wool packaging material (I got a bunch of it on freecycle from someone who gets lots of food delivered insulated with it), put the lid on and put more wool on top, then left it in the greenhouse.

After 24 hours, it looked like this, with a nice metallic sheen on top. The fabric you can see is a bit of muslin I used to wrap the leftover leaves from the ice extraction in; I wanted to get the remaining colour out of them without filling my dyebath with tiny bits of plant. It was still pleasantly warm, wool is a really good insulator.

I fished out all the leaves into a mesh bag, and was left with turquoisey coloured liquid.

I made sure to squeeze all the liquid out of the leaves into the dyebath.

This darkened it considerably

The dyeing process is faster at higher temperatures (so long as you don’t go over 60C as this will destroy the pigment once it’s been reduced), so I got to play with my new toy, a portable hotplate I can use in the utility room/garden when I don’t want to make mess in the kitchen or do stinky plant stuff indoors. I managed to heat it up to around 40C before excitment overcame me and I moved on to the next stage.

The next stage was to get the pH to a suitable level. I have UI paper, and also a very handy pH meter that I bought to check my tomatoes are acidic enough when canning. I calibrate it before using for that, but for this I didn’t bother, I just checked my tap water was around 7 and called it good enough.

From my reading earlier, I’d decided to use in the region of 10g of sodium hydroxide. I put some of the dyebath in a mug and added just over a teaspoon of it, and stirred until it had dissolved, then poured it into the dyebath. Testing revealed the pH was 10.8. Perfect. On adding the alkali, the dyebath turned a dark green colour.

I took it back outside and aerated it by repeatedly lifting some out and pouring it back in. I did this for a few minutes until I was bored and my arm was tired.

I then added the hydros. I gave the bath a stir to create a vortex, then poured in about 30g, I didn’t weigh it, just estimated. I stirred it a little then put it back in the wool-lined box in the greenhouse for an hour.

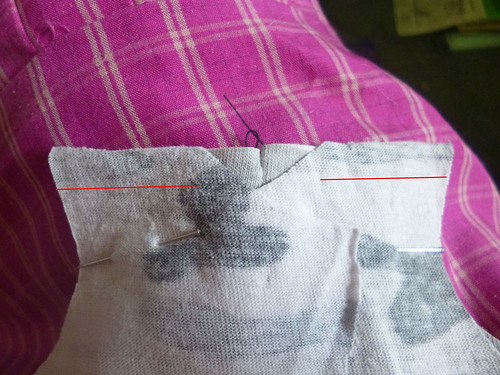

During that hour I prepared my fabric. I decided to dye some muslin, some cotton tote bags, and some shibori thread. I put the fabric through the wash the night before to make sure it was scoured, and washed the thread by hand with some washing up liquid. While my dyebath was reducing I took this clean fabric and had fun with tying it in various ways.

After an hour, it was time to go! The dyebath was a bright neon yellowy green, with more metallic sheen on top. I tried to move this top layer out of the way before dyeing, with partial success. The bits that remained didn’t seem to affect anything negatively though.

I put my stuff in, squeezing as much air out as possible and holding it tightly in my hands before placing underwater and letting go. I decided to go for volume rather than depth of colour with this first attempt as I’d like to have enough fabric to make a dress out of. I left the stuff in for 10 minutes at a time before removing gently and allowing to oxidise, and then returning to the dyebath. Here are a few more pics.

Green dyebath:

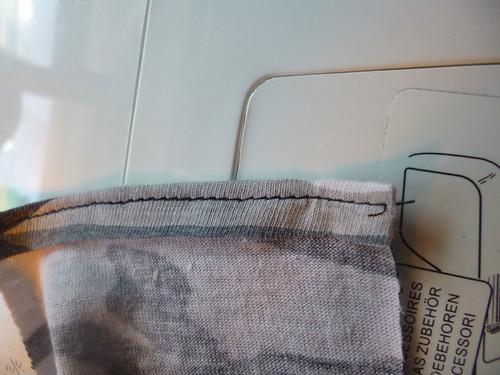

Out and mostly oxidised. The thicker fabric at the hem of the bag has more liquid in and is still greenish coloured

Drying things

And the first lot dry. It’s paler than I was expecting, but it’s a lovely sky blue colour, so I’m happy with it.

I’ve now, about 8 hours later, just put the whole lot in the washing machine on a quick cycle to rinse out any excess dye, and I’ll try and update this post with photos once it’s all dry. The dyebath isn’t fully exhausted I don’t think, so it’s back in the greenhouse. Over the next couple of days I will try lowering the pH and dyeing some wool in it, and perhaps adding some synthetic indigo and having a try for deeper colours.

I will definitely be growing japanese indigo again next year, and if I’m lucky I’ll get another harvest this year. It’s been a really interesting and fun process, and I just love the colours it gives.